17th September 2005 was the date for the next robotics competition, which gave us about 3 weeks to build our robot.

We had to start from scratch. The first thing Rajiv wanted was a frame. We didn't want a robot that was just a steel plate with stuff mounted on it, a la Ranchubot. We wanted something that looked good, and not like every other robot that one would typically see at such competitions. That's because our aim was very different I guess - we were more interested in building the robot than winning the competition.

Having seen the sort of stuff others would enter into competitions, we wanted to show them how it's done - our robot would be fast and powerful, capable of turning on the spot, intelligent, and above all, solid.

I suggested we build a frame using stainless steel pipes welded together, and use 4 motors - one for each wheel - to achieve maximum torque and turning control. The electronics would be Rajiv's department, and I would handle the mechanical and coding aspect of our project.

Rajiv's work was cut out for him - the circuit on our new robot would be pretty much like the one on the old one, just a lot more complex cos we had 4 motors to drive, and we had settled for using 16 Infra-Red sensors to track the silver line the robot would have to follow. Our original design was to have 20 sensors in fact, placed in 2 rows of 10 each, but we realized that 20 sensors would need 3 multiplexers, making the circuit unnecessarily more complex. So we settled for 16 since that could be achieved using just 2 multiplexers. Just to put this into perspective, the other robots would usually have 2 or at best 4 sensors. But all those strategy games - controlling huge armies and building grand bases - had clearly given Rajiv and me a hint of megalomania.

Sounds straightforward enough…

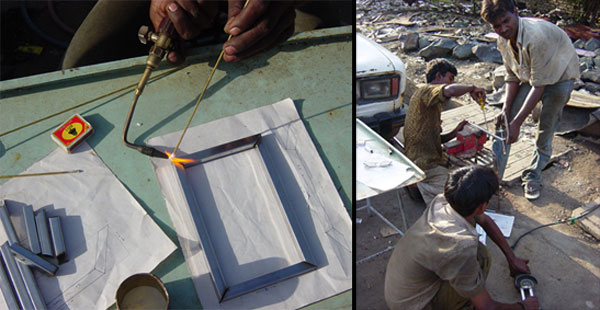

We got down to actually putting together the parts we had acquired for the robot only in the last week that we had. Don't ask me why. We seemed to have been sitting around waiting for Pok to play with us (as described in the previous episode) in spite of having a robot to build. While Ranji soldered the stuff together I spent hours visualizing what the frame should look like. Once I had it figured out, I drew out what looked kind of like an engineering drawing (using all the fancy stationery stuff we had thanks to the subject of the same name at college). I say kind of, because it had to be thoroughly simplified. I'd have to get the welding job done by a car mechanic, so it had to be in a form that made sense to even the worst of their kind, so that the end result would look something like what we wanted.

We now had 3 days left and I entrusted Rajiv with getting the frame welded together as I had to go to college to attend a lecture I had zero attendance in. Zero. That, by the way, is a situation I was most proficient at getting myself into.

I come back to see this…

"Another day, another frame", was my solution to the entire mess. I spent the night designing a more complicated frame for our robot. I know, you're probably thinking, "the guy screwed up a simple one, why make it more complicated?" The idea behind the complexity was to make it foolproof - it makes sense really, if you think about it.

Learning from my mistake with the previous design, I designed the new frame in separate parts. By doing this I ensured I would get at least the lines straight on critical parts of the frame - such as the base onto which the motors will be attached, and the secondary frame for attaching the main PCB. Both the base sections of the frame were simple rectangles this time. All fancy angles were reserved for more cosmetic parts like bumpers, etc. which would be fabricated separately and welded onto these base sections in the end. Bumpers? You'll see soon enough.

It took from somewhere around then till 6 PM to get the basic parts of the frame assembled, with a break of about 2 hours in between for lunch. So now it was time to finally braze all the separate parts together to get the finished frame. Brazing? Oh yeah, I forgot to mention - we weren't doing any welding here, contrary to what I had expected. Brazing is similar to welding, but it's more like soldering because you melt a 3rd metal to join 2 pieces of metal together, using a blow torch. Blah.

Yeah so, as I was saying, it was 6 PM… and suddenly, the heavens decided to share some of their moisture with us. Perhaps the Gods were happy with the fact that my frame was almost complete. Just half an hour ago it had been sunny, and now it was pouring. Luckily the Maruti Van was in no better shape than it was at 9 AM, so we walked in and continued our brazing inside the van. The guys did also have a cup of tea in there while it rained - as I had earlier suggested would be a swell alternative to getting run over.

You're probably thinking, "Hang on a minute. Tea is fine, but brazing? Inside the van???"

It wasn't my idea, I swear. Perhaps Bhushan (the car mechanic for those of you who suck at Memory) felt the same way about the van as I did after all. So the frame was completed inside the van, while it poured outside. Then, just as we were done, the rain conveniently stopped. I got the holes in the frame filled in with Body Solder (some green goo that was smothered on in copious quantities) and headed home.

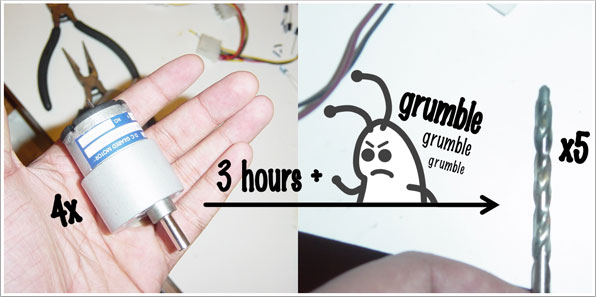

And if you thought everything was going well with the frame, let me sum it up with an equation I discovered:

4 motors x 2 bolts each = 8 holes to be drilled = 5 drill bits + 3 hours + n expletives

where n is any arbitrarily large number.

Watch the intriguing drama unfold as she mutilates the 5 pricks that tried to penetrate her… one by one

As we moved closer and closer to completion, the robot showed us it had no intention of being complete just yet. Not quite the intelligence we intended for it to have. Problem after problem crept up like roaches in a drain pipe to hell. Time was running out now as fast as Infra-Red LEDs. The darn things didn't seem to be working either. I think we spent most of the day just correcting problems that we kept uncovering with the existing circuit.

We worked till 3 AM that night. We were tired and frustrated. But we somehow managed to convince ourselves to give it all we've got the next morning and then go for the competition. It was scheduled for 1:30 PM, so that gave us enough time, as per our still-optimistic calculations, to

- brush our teeth, and

- get the robot ready for its big day…